Congratulation on the PhD!

PR Metallurgie2024-04-22T10:53:47+02:0022/04/2024|

STAMMTISCH. with Wieland Austria Ges.m.b.H.

PR Metallurgie2024-04-16T11:10:33+02:0003/04/2024|

Study Metallurgy

Metallurgy at the Montanuniversität Leoben

Why Metallurgy?

8 Reasons to study metallurgy in Leoben

Reason 1: Metallurgy in Leoben is – an excellent education on the highest level

In 2023 the Montanuniversity Leoben was rated by the international Shanghai Ranking, which rates international universities, and placed 21th internationally in “Metallurgical Engineering”. In the European [...]

Reason 2: Metallurgy in Leoben is – a sociable campus life in Leoben with a great community

The city of Leoben has a charming flair and directly in the city center there is the university campus. The students in Leoben know each [...]

Reason 3: Metallurgy in Leoben is – a surety for great professional prospects

In Austria you only can study metallurgy in Leoben, therefore our alumni are very sought-after. Metallurgists are needed in each field of the metallurgical industry [...]

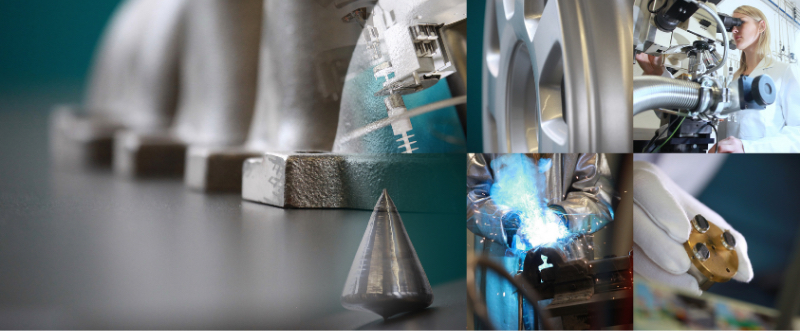

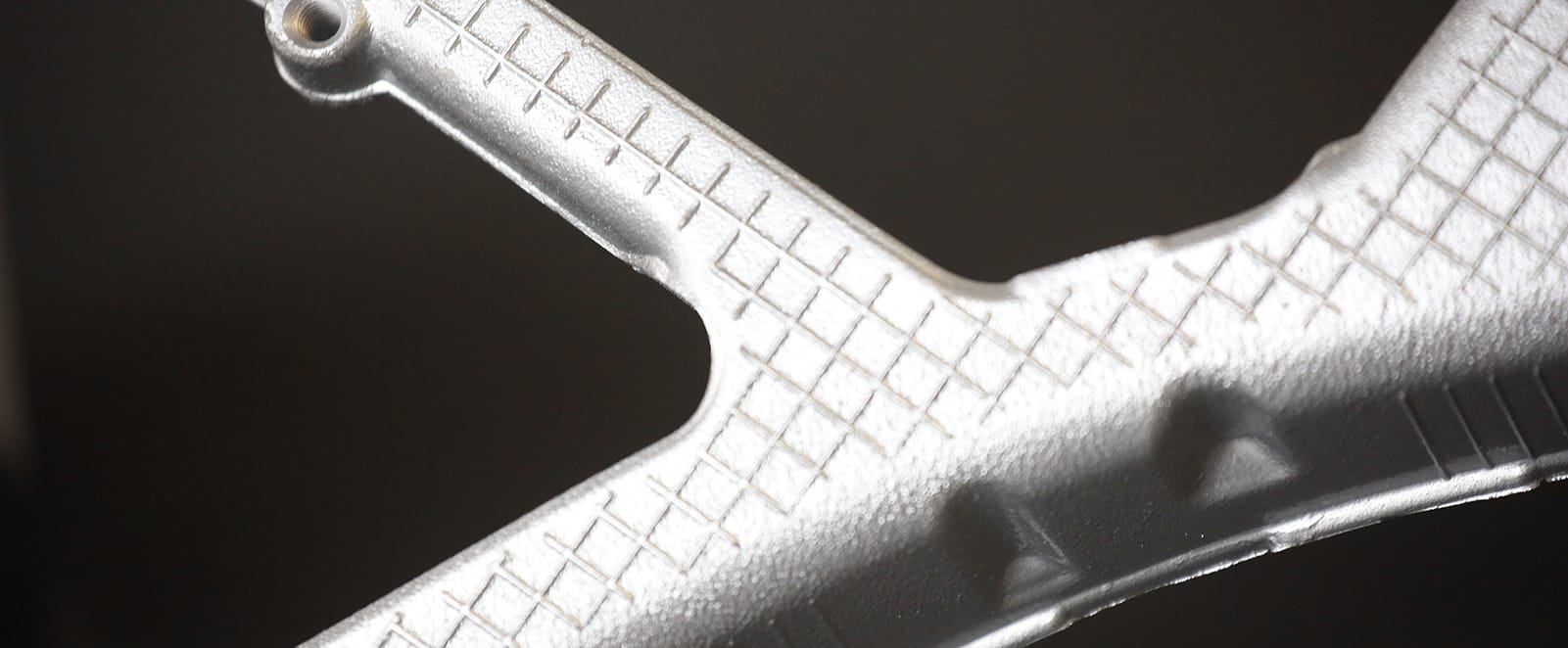

Reason 4: Metallurgy in Leoben is – working with innovative metallic materials

Have you ever thought about how many metals are in the periodic table of elements? And which specific properties they all have? Now think about [...]

Reason 5: Metallurgy in Leoben is – supported by numerous industry partners

You want to have some insight in the industry during your studies and have the opportunity to get exciting internships with thrilling industry partners? Then [...]

Reason 6: Metallurgy is – the possibility to study at international partner universities

You always wanted to study a semester abroad? Whether you want to spend a semester in exotic destinations like Brazil or Australia or rather at [...]

Reason 7: Metallurgy in Leoben is – a chance to be part of a Mentoring Program – optional support from professors in the beginning of your studies

In Leoben, we have an excellent proportion between professors and students and we want our students to profit from this fact. Especially the first years [...]

Reason 8: Metallurgy in Leoben is – the chance to be part of thrilling research projects

The study program of metallurgy in Leoben is unique in Austria and has a very good reputation. Due to this reason industry partners come to [...]